Wastewater Recycle System

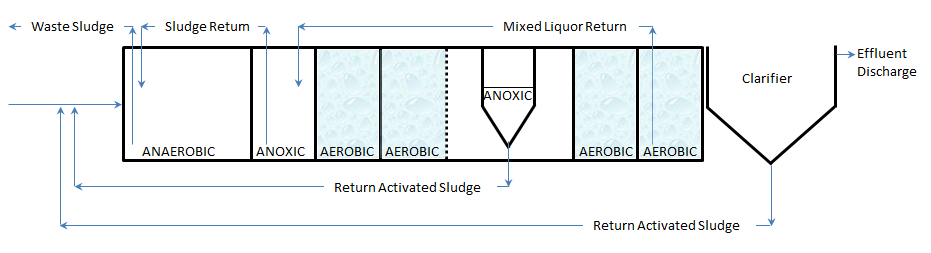

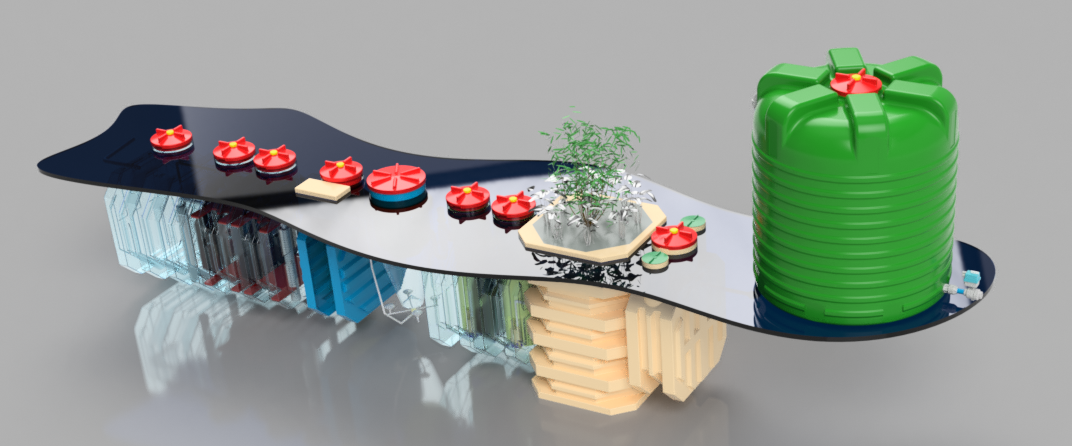

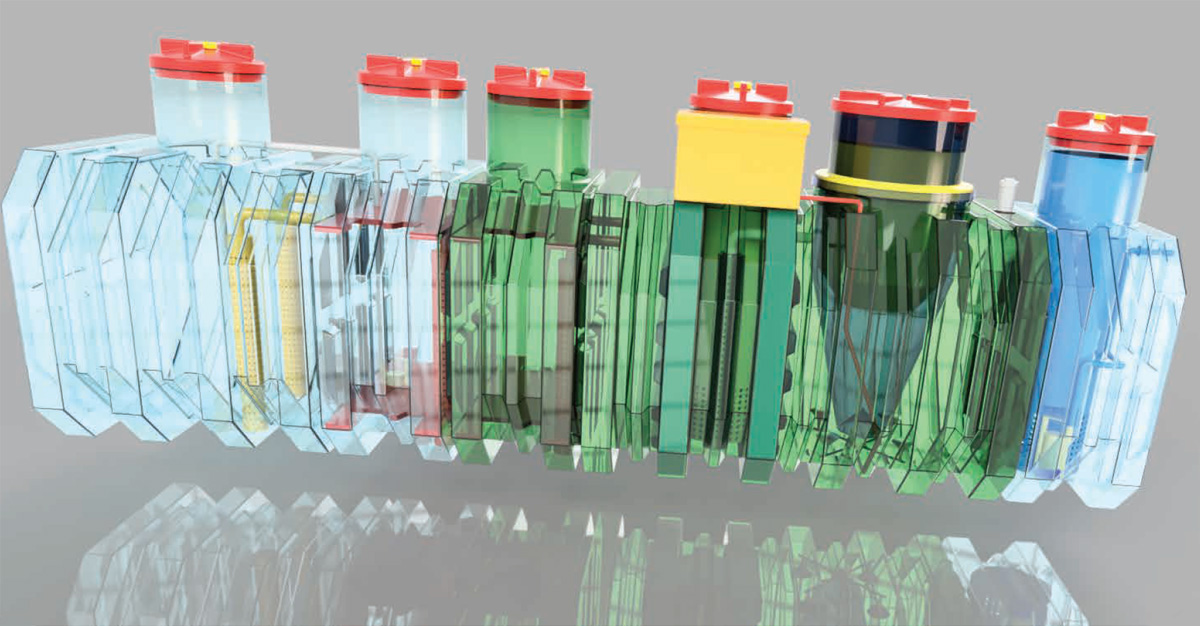

| ECO SMART INTEGRATED FIXED FILM ACTIVATED SLUDGE AND MOVING BED BIOLOGICAL REACTORS WASTE WATER TREATMENT SYSTEM The onsite ECO Smart Integrated Fixed Film Activated Sludge and Moving Bed Biological Reactors Waste Water Treatment System is a self-contained sewage treatment system that utilises a combination of anaerobic as well as aerobic biological processes, combined with an absorption filtration system to treat wastewater generated on-site. The waste water treatment system comprises a six-stage waste water treatment system operating much like a small municipal sewage treatment plant, resulting in a clean, septic effluent. The system also has a modular design and the treatment capacity can be adapted to treat a wide range of operating requirements. This system is designed to handle a continuous flow of wastewater by relying on bacteria suspended in the sewage to break down solids, as well as employing the absorption filtration technology to remove other contaminants. The process includes anaerobic, 1st anoxic, 1st aerobic, 2nd anoxic and 2nd aerobic (MBBR) reactors in series with 2nd stage aerobic mixed liquor recycle to the 1st stage anoxic reactor, 1st stage anoxic reactor sludge recycle as well as return sludge recycle from both clarifiers to the anaerobic reactor. Importantly, the ECO Smart Integrated Fixed Film Activated Sludge and Moving Bed Biological Reactors Waste Water Treatment System operate on gravity and no feed pumps are therefore required. The suspension and aeration are supported by an aeration pump that supplies air to the bio-filtration process, the aerobic bacteria generator chamber, and the aeration chamber, thus providing a constant stirring of the wastewater in addition to the oxygenation. For our Recycle Sanitation System, suitable for all areas off grid i.e., with no sewer and/or electricity services available, this design has been adapted to include an aerated biological filter as well as a cistern inline absorption filter to ensure that high-quality effluent is supplied to the toilet cistern. |

|

Six Stages of the ECO Smart aerobic wastewater treatment system

|

|

Stage 2: Aerobic Attached Growth Bio ReactorThe aerobic attached growth (packed bed) bio-reactor contains the biological filtering system, where the bio-filtration process takes place. It contains a medium onto which microorganisms attach and grow under aerobic conditions to form a biological layer called the biofilm. The wastewater now flows over this medium where the organic matter and other water components diffuse onto the biofilm and treatment occurs, mostly by biodegradation.Stage 3: Aerobic Bacteria GeneratorWastewater enters the aerobic bacteria generator chamber from the anaerobic/anoxic reactors through the aerobic bio-filter. In the aerobic bacteria generator − a bio-filtration system that is designed to promote fixed film bacterial growth in order to handle higher-than-normal levels of biomass in the wastewater − waste continues to be broken down and digested. The chamber comprises a bundle of straight tubes used in what is called a ‘submerged packing process’; the wastewater is circulated through these tubes under aeration so that aerobic microorganisms are generated on the surface of the individual tubes as films. The various organic substances that come into contact with the films are then decomposed in this section of the system. At this stage the main focus is also to enhance the nitrification process by ensuring a high level of dissolved oxygen present.Stage 4: SettlingClear, odourless effluent rises into the clarifier chamber from the bottom up during the settling out stage of the process. The cone-shaped clarifier ensures that any fine solids still present in the wastewater sink down and is transferred back to the anaerobic chamber through an air suction process. The clarifier also contains the de-nitrification filtering chamber which is fitted with an absorption filter (de-nitrification filter) as well as a water circulation pump. Wastewater passes from the clarifier into the de-nitrification filtering chamber, where it is continuously circulated through the absorption filter by the water circulation pump, enhancing the wastewater quality by removing phosphates, nitrates, heavy metals, and other dissolved contaminants. |

Stage 5: Moving Bed Bio ReactorThe moving bed bio reactor employs thousands of polyethylene biofilm carriers operating in a mixed motion within the aerated reactor space. Each individual bio carrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high density population of bacteria that achieves high rate biodegrading within the system, while offering process reliability and ease of operation. Minimal maintenance is required as the MBBR processes self-maintain an optimum level of productive bio film. Mixed liquor return from the 2nd MBBR to the 1st stage anoxic reactor further promotes the de-nitrification of ammonia. |

Stage 6: Tertiary Filtration and Disinfection ProcessThe tertiary filtration and disinfection process in the final filtration chamber is a post treatment step to remove pathogens, residual suspended solids and/or dissolved constituents through a surface filtration process i.e. by means of a mechanical sieving. This final filtration chamber also contains the settling out clarifier from where the return activated sludge is recycled back to the anaerobic reactor. |

Soak AwayAccess effluent, which is highly treated and is according to and complies with the Special Standards as prescribed by the Ministry of Agricultural, Water and Forestry, is discharged into the soak away through the system overflow.The soak away consists out of 6 lengths of 6 meters long, 40 mm dia. PVC pipes perforated with 5 mm dia. holes buried at a depth of no less than 600 mm in a bed of 19 mm dia. gravel covered with a plastic sheet at a depth of 400 mm below ground. |

|

Discharge standards, general standard limits

PH 5.5 - 9.5

Conductivity 150; 70 above water supplied mS/m

Total Suspended solids 25 mg/l

Chemical Oxygen Demand 75 mg/l Ammonia (as N) 6 mg/l

Nitrate (as N) 15 mg/l

Fecal Coliforms 0 CFU/100ml

Operation and Maintenance

The system is designed to avoid complicated operation. The only moving parts are the submersible, sludge and air pumps which operate automatically and are controlled from the electrical control panel.

Sludge Management

The Aerobic Bacteria Generator system produces small quantities sludge and is broken down into methane gas, carbon dioxide and water. Depending on the volume and BOD influent values the system will require minimum de-sludging.

Disinfection

For this application we recommend final disinfection using chlorine pills dispersed through an Eco SMART chlorinator.

Commissioning

Generally, the system takes 2-3 weeks to run optimally from start-up. Bacterial seeding is required. Foaming can occasionally be seen during the initial start-up period but settles down once the bacteria bio film has established.

Warranty

5 years on the structure

1-year manufacturer’s warranty on aeration pumps.